Machines

-

WH Mini travelling screen press (V2A)

WH Mini travelling screen press made of stainless steel, with air compressor, switchgear cabinet and belt-type washing system using a choice of fresh water or water treatment plant. The machine is fully operational on delivery, complies with the latest state of the art, including all the related components - fluid level controller, safety switch and control system. Only approved materials are used to construct the machine. Bought-in parts such as the motor, pumps, gearbox, electrical switches, compressed air switches and standard parts can be obtained at any time (no spare parts problems). Bearing housings are made entirely of stainless steel.

Dimensions:length 2100 mm / width 1200 mm / height 800 mmPress weight:1000 kgCapacity:750 kg per hour -

WH2 screw-type elevator with fruit crusher (V2A)

Lifts apples and pears and comprises washing container, overflow outlet and drain valve for waste water. The conveyor screw is driven by an electric motor. With automatic safety switch to cut out the conveyor screw when the water return box is opened.

Directly flange-mounted fruit crusher, made of V2A, with casing for scoring knife and 3 kW electric motor. Complete with mash discharge funnelPipe diameter:267 mmDrive power:1,5 kWConveying capacity, depending on type of fruit:approx. 1.5-3 t per hourLifting height:according to customers' requirementsCapacity:3000 kg per hour -

Fruit cutters

Fruit crusher made entirely of V2A with casing for scoring knife and feeder screw. Various types of scoring knife can be installed to achieve the optimum mash texture. The entire crusher is mounted on a baseplate and driven by an electric motor through a clutch.

Capacity:up to 40,000 kg per hour -

Stainless steel masher (V2A throughout)

With casing for scoring knife.

The desired configuration of the machine can be adjusted in order to achieve the optimum yield. Mashers are available in various sizes with capacities up to 8000 kg per hour.They can be combined with a washing system and mash pump.

-

High silo (bolted assembly) made of hot-dip galvanized steel.

All silo components are made of stainless steel.

The silo is ventilated and, being made of stainless steel, is guaranteed to provide hygienic storage. Sorting facilities are also available for use when filling and emptying, and fruit can be extracted at any point along the entire length of the silo. Thanks to its modular design, the silo can accommodate additional extensions. If it needs to be moved to another site, it can be dismantled and rebuilt without difficulty and construction costs are modest.

High silo parts:

High silo, discharge belt (length 23 m), distributor belt with flap, loading belt for transport vehicles.Dimensions:length 23 m / width 4 m / height 4.5 m, depending on customers' requirements.Volumetric capacity:approx. 2400 x 50 kg of fruit, divided into 5 boxes. -

Sorting conveyors

Roller conveyors with integrated sorting system, made entirely of V2A, with lateral dirt discharge and adjustable spray system at the feeder end.

The sorting conveyor consists of serrated rollers which rotate for grading purposes. The bearing housing is made of stainless steel. The drive system is either an infinitely variably adjustable gear motor or employs a frequency converter.

Conveyor width and length according to customers' requirements. -

Juice strainer

V2A juice strainer, designed to perform the continuous filtration of solids from liquids.

The strainer drum can be removed for cleaning purposes and the angle of inclination of the drum can be infinitely variably adjusted

Capacityaccording to customers' requirements. -

WH 2 / WH 3 / WH 4 screw-type elevators

Lifts apples and pears and comprises washing container, overflow outlet and drain valve for waste water. The conveyor screw is driven by an electric motor.

With automatic safety switch to cut out the conveyor screw when the water return box is opened.Capacity:Up to 40,000 kg per hour -

BS bow sieve (V2A)

BS bow sieve (V2A) for cleaning waste water, made entirely of stainless steel and with removable sieve lining. The lining is cleaned automatically.

Size:according to capacity. -

Pasteurizer

Compact pasteurizing plants with a plate-type or tubular heat exchanger, heating furnace and burner with heating circuit installed, digital thermometer and control valves.

The plant adjusts itself automatically.

The entire pasteurizer is mounted on a transportable base frame. An oil- or gas-fired burner can be used for heating purposes. Either system should be connected to a flue gas exhaust system.Capacity:300-1000 litres per hour -

-

Bag-in-box filling plant

Bag-in-box filling plant of modular design.

The semi-automatic version can also be retrospectively converted to operate fully automatically.

Bag-in-box automatic filling plant (semi-automatic) manual procedure:- Place an empty bag in the machine.

- Remove the plugs.

- Press 'Start'; the filler pipe traverses into the bag and the preselected volume of juice is filled.

- Re-seal the plugs.

- Pack off into the bag-in-box carton.

Automatic bag-in-box filling plant (fully automatic) procedure:Place an empty bag in the machine. A gripper will then remove the plugs from the bag and fill the preset volume of juice. Following this, the bag is automatically sealed with plugs and, at the same time, a label is prepared for identification purposes. The bag is then ejected from the machine and can be conveniently packed off.

-

Screw conveyor made of V2A

We make standard screw conveyors in various lengths and diameters, according to the type of material conveyed.

We also make hoppers and discharge screws in a variety of configurations, depending on customers' requirements.

Example:-

1 Screw conveyor made of V2A with covers which can be

hinged open - Protected by limit switches

-

Diameter 323 mm x length 9100 mm, made in individual

segments for screw assembly. - Screw blade, 3 m wide

- Thick-walled screw shaft tube

- The screw shaft features three intermediate bearings

-

Powered by 5.5 kW electric worm drive motor with

adjustable frequency converter.

-

1 Screw conveyor made of V2A with covers which can be

-

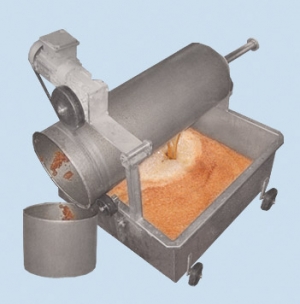

Stone separating machine

The hot mash, containing stones, is introduced directly from the cauldron into a rotating V2A drum. Thanks to the special shape of the screening drum, the stones are separated from the mash and caught in a separate container.

Made entirely of stainless steel

OH 400 stone separating machine

Dimensions: length 900 mm / width 600 mm / height 850 mm

Height of mash inlet: 550 mm

OH 600 Stone separating machine

Dimensions: length 900 mm / width 600 mm / height 950 mm

Height of mash inlet: 650 mmPower supply:0.25 kW -

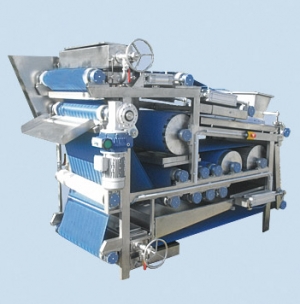

WH Compact travelling screen press, (V2A)

WH Compact travelling screen press made of stainless steel, with air compressor, switchgear cabinet and belt-type washing system for belt cleaning, using a choice of fresh water or water treatment plant. The machine is fully operational on delivery, complies with the latest state of the art, including all the related components - fluid level controller, safety switch and control system. Only approved materials are used to construct the machine. Bought-in parts such as the motor, pumps, gearbox, electrical switches, compressed air switches and standard parts can be obtained at any time (no spare parts problems). Bearing housings are made entirely of stainless steel.

Dimensions:length 2800 mm / width 1350 mm / height 1930 mmPress weight:1500 kgCapacity:1500 kg per hour -

WH 65 oil-hydraulic swivelling packing press

The press frame consists of a robust, welded steel structure. The swivelling frame is mounted on ball bearings, while the press containers are made of stainless steel. The hydraulic pump is mounted on the press. This is fully equipped with 26 acacia-wood grids (65/65 cm) and 30 press cloths (100/100 cm).

Press weight:850 kgDrive power:101 kWPress capacity:1100 kg of fruit per hour -

WH travelling screen presses

WH 800 V2A / WH 1000 V2A / WH 1200 V2A / WH 1500 V2A

With air compressor, switchgear cabinet and recirculating-type washing system, the latter consisting of a bow sieve (which cleans the water for re-use), a forcing pump and a circulating pump. The machine is fully operational on delivery and complies with the latest state of the art, including all the related components - the fluid level controller, safety switch and control system. Only approved materials are used to construct the machine. Bought-in parts, such as the motor, pumps, gearbox, electrical switches, compressed air switches, ball bearings and screening belts all bear well known brandnames and are standard parts which can be obtained at any time (no spare parts problems).Dimensions:length 3500 mm / width 2000 mm to 2400 mmDepending on size:height 2400 mm -

SPU600 Packing press

1 SPU600 II oil-hydraulic swivelling packing press.

The press frame consists of a robust, welded steel structure; all the materials have been newly painted. The swivelling frame is mounted on ball bearings. The press containers are made of stainless steel. A hydraulic pump is mounted in the press.The press is fully equipped with 22 acacia-wood grids

(65/65 cm) and 20 press cloths (100/100 cm) korro 66V.Drive power:1.1 kWCapacity:1000 kg of fruit per hourTotal pressure:35,000 kgWeight:900 kg -

WH55 Special oil-hydraulic swivelling packing press

The press frame consists of a robust, welded steel structure. The swivelling frame is mounted on ball bearings, while the press containers are made of stainless steel. A hydraulic pump is mounted on the press, which is fully equipped with 20 acacia-wood grids (55/55 cm) and 30 press cloths (100/100 cm).

Weight:350 kgDrive power:1.1 kWCapacity:800 kg of fruit per hour -

WH65 oil-hydraulic swivelling packing press

The press frame consists of a robust, welded steel structure. The swivelling frame is mounted on ball bearings, while the press containers are made of stainless steel.

A hydraulic pump is mounted on the press, which is fully equipped with 20 acacia-wood grids, (65/65 cm) and 30 press cloths (100/100 cm).

Weight:850 kgDrive power:1.1 kWCapacity:1100 kg of fruit per hour -

SPU 800K swivelling packing press

With two new V2A press containers and a central juice collecting container. Cladding panels are made of V2A. The press features a combination of a two-stage, pressurised oil pump mounted in a liquid container.

Press speed in low pressure infinitely variably adjustable.

The press is fully equipped with 24 acacia-wood grids (80/80 cm) and 22 new press cloths (160/160 cm), korro 66V

Special accessories:- 1 High-speed packing device made of V2A

- 1 Press cladding panelling made of V2A

- 1 Press cladding panelling made of V2A

- 1 Stroke limiter

Capacity:1000 kg of fruit per hourPaint colour:RAL 5012Pressure capacity:high pressure, 280 barPressure capacity:low pressure, 60 bar -

-

-

-

-

-

Sorry, no image available.

-

-

-